Die casting & Die casting parts, this metal production method is for high-volume production, especially for small to mid-size parts. During the die casting process, molten metal is injected into a mold cavity under high pressure. Normally, Aluminum alloy die casting & Zinc/ZAMAK alloy die casting is two kinds popular die casting methods.

Get a Free Quotation and Price for your Aluminum Or Zinc Die casting products, Pls. email us: cnkylt@aliyun.com

Which Metals can be used for die casting?

Most non-ferrous metals can be used in die casting. In KYLT, our materials involve Aluminum, Zinc, Lead and Magnesium alloys.

The molds are also called Die casting Mould /Dies, Injection tooling.

Get a Free Quotation and Price for your Aluminum Or Zinc/ZAMAK Die casting mould/mold/die, Pls. email us: cnkylt@aliyun.com

What are the Die Casting advantages?

Suitable for a range of metal alloys, die casting has the following advantages:

- Saving cost, not only in the part price itself but also in the overall cost of production.

- Produces complex parts to net shape, reducing secondary machining

- High-speed production compared to other manufacturing processes

- Die cast parts are durable and have a long service life

- Produces components with attractive, high-quality surface finishes

- Produces a broad range of shapes and surface textures

- Variable wall thicknesses

- Simplifies the assembly process by integrating fastening elements

- Fewer steps from raw material to the finished part

- Tighter tolerances

In KYLT, We have Cold chamber die casting machines and Hot chamber die casting machines to produce: Aluminum, Zinc/ZAMAK, Lead, Magnesium Die casting parts. ( Get a Free Quotation and Price for your Aluminum Or Zinc/ZAMAK Die casting products, Pls. email us: cnkylt@aliyun.com )

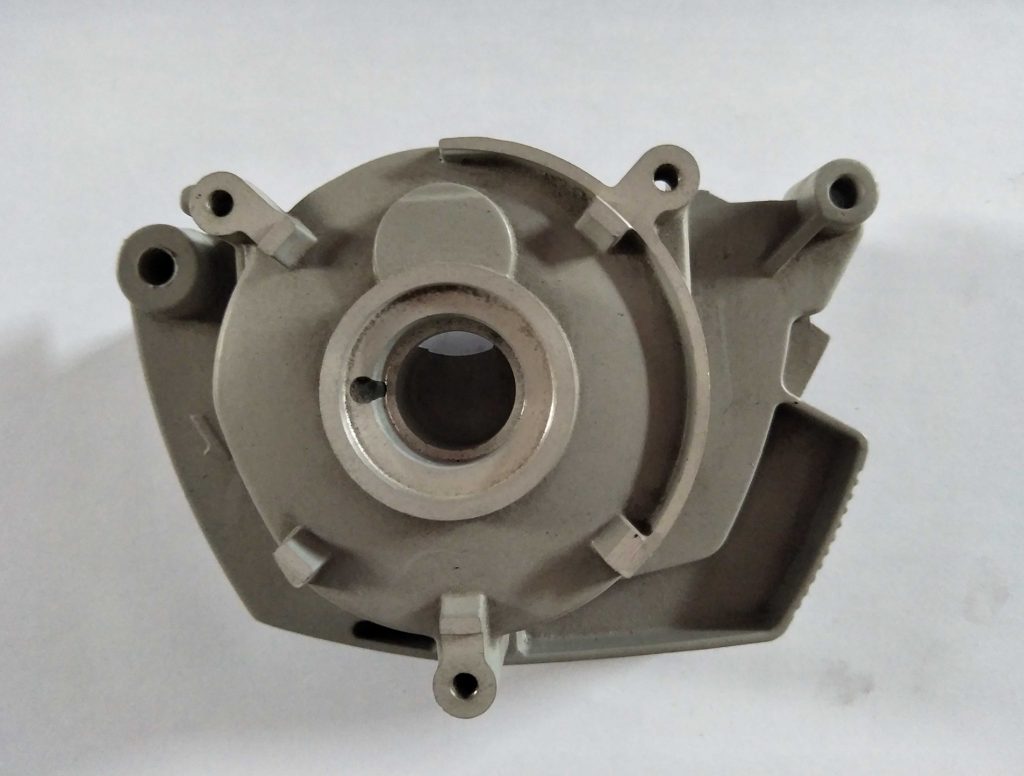

Aluminum Die casting parts, made by 200-500T cold chamber die casting machines:

Zinc / ZAMAK DIE CASTING PARTS, SMALL SIZES PARTS MADE BY HOT CHAMBER DIE CASTING MACHINES, MIDDLE & BIG SIZES PARTS MADE BY COLD CHAMBER DIE CASTING MACHINES:

MAGNESIUM DIE CASTING PARTS, MADE BY MAGNESIUM COLD CHAMBER DIE CASTING MACHINES:

Surface treatment or finishes of Die Casting Part:

- Only die cast surface

- Polishing finish

- Shot blasting finish

- Painting surface

- Powder coating

Machining services for Die Casting part:

- CNC Milling

- Drilling

- Tapping

- NC Turning

- EDM

- WEDM

- Welding

Die casting parts price:

The calculation of a die casting part price involves material cost, injection cost, trimming cost, machining cost, surface finish cost, packing cost etc.

Send your die-casting project 2D/3D drawing to: cnkylt@aliyun.com , to get a free quotation now.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum/Zinc (Zamak) die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology: