At the request of Iranian medical device customers, our factory will provide them with a complete set of Skin staplers injection molds, metal accessories, and skin stapler nails feeding machines.

Skin stapler spare parts and molds

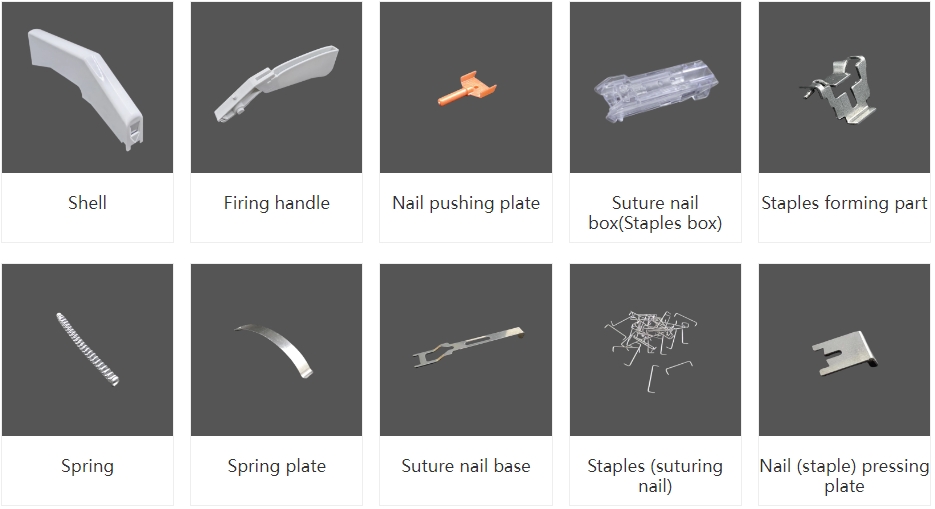

The entire skin staplers project involves a total of 10 parts, need 4 sets of plastic injeciton molds.

– Skin stapler shell and its plastic injection mold

Made from ABS plastic material, one mold 4cavites. The shell/handle of the entire skin stapler serves as the structural framework and provides the necessary space for assembling the various components.

Skin stapler shell injection mold structure and injectoin test video:

Youtube: https://www.youtube.com/shorts/KWeMPb6QgnQ

– Skin stapler firing handle and its plastic injection mold

Skin stapler firing handle made from ABS material, one mold 2cavites . As a trigger mechanism, it governs the deployment of the staples, enabling accurate positioning and tension regulation.

Skin stapler firing injection mold structure and injectoin test video:

Youtube: https://www.youtube.com/shorts/p1TMC1IG3BE

– Skin stapler nails pushing plate and its plastic injection mold

This nail pushing plate made from ABS, one mold 10 cavities. After each sewing action is triggered, the staples pushing plate advances the next staples and keeps them within the working range.

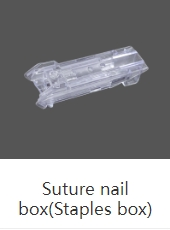

– Skin stapler Suture nails box and its plastic injection mold

Skin stapler sutural nails box made from PC material, one mold 4cavities. The plastic part holds the staples and provides support and alignment they are used.

Skin stapler firing injection mold structure and injectoin test video:

Youtube: https://www.youtube.com/watch?v=gyLVMFiyjM4

– Skin stapler metal parts show:

Made from stainless steel wire. Designed for suturing wounds, each skin stapler includes 35 staples. (Note: in assembling process, we need feed 40pcs nails into the suture nail box. After assembling , we will inject 5 shots to test the skin stapler.)

The stapler nails feed process, the use of auto feeding machine is a key element. The use of this machine improved the nails feed quality, saved cost, and very fast. More information, please contact us : cnkylt@aliyun.com ; And, you can read our blog : What Is Auto Skin Stapler Nails Feeding Machine?

Reference photo of Auto skin stapler nails feeding machine:

Skin stapler spare parts list

| 1. SHELL | ABS | As the handle of the entire skin stapler, it provides structure and installation space for the assembly of various parts. |

| 2. FIRING HANDLE | ABS | As a trigger mechanism, it controls the firing of the staples, allowing precise placement and tension adjustment. |

| 3. NAIL PUSHING PLATE | ABS | After each sewing action is triggered, the staples pushing plate will push the next staples into and maintain it within the working range. |

| 4. SUTURE NAIL BOX | PC | Worked as the function of staples cartridge & housing, to hold and house the staples cartridge and provide support and alignment for the staples during deployment. |

| 5. STAPLES FORMING PART | STAINLESS STEEL | Used for bending and sewing, achieving the function of skin wound suturing. |

| 6. SPRING | STAINLESS STEEL | Used to push the nail pushing plate, thereby pushing the saples forward. |

| 7. SPRING PLATE | STAINLESS STEEL | Used to control the rebound of the firing handle. |

| 8. SUTURE NAIL BASE | STAINLESS STEEL | After the suture staple is formed, separate it from the skin stapler. |

| 9. STAPLES | STAINLESS STEEL | Used for suturing wounds. Each skin stapler comes with 35 staples. |

| 10. NAIL PRESSING PLATE | STAINLESS STEEL | Working together with the staples to form metal parts, pressing and bending the staples to sew the wound. |

More information and questions, please email us: cnkylt@aliyun.com

FAQs

1. What spare parts are included in the full set for a skin stapler?

This typically includes shell, firing handle, nail pushing plate, suture nail box, staplers forming part, spring, spring plate, suture nail base, staples, nail pressing plate.

2. Can you provide customized molds for skin stapler manufacturing?

Yes, customized molds can be designed and manufactured to meet specific client requirements and device specifications. Just send your skin stapler samples or drawing to us, we will quote for them immediately. Service Email: cnkylt@aliyun.com

3.What materials are used for the molds and spare parts of skin staplers?

Molds are usually made from high-grade steel for durability, while spare parts are made of medical-grade materials such as stainless steel and biocompatible plastics.

4.What is the typical lead time for supplying the full set of spare parts and molds for skin staplers?

Lead times vary depending on order size and customization but generally range from 8 to 12 weeks.

5.Do you provide technical support and installation guidance for spare parts replacement?

Most suppliers offer technical documentation, video tutorials, and customer support to assist with part installation and maintenance.