CNC Lathe Turning Service, CNC Turning is a high-precision, high-efficiency machining method of automatic lathe with digital control and cutter tools change. In which bars or blocks of material are held in a chuck and rotated while the cutter is fed to the workpiece to remove material,then to create the drawing required shape.

As a professional CNC Turning Services Supplier in China ( or we call CNC Lathe Services), Just send us your desired design by email: cnkylt@aliyun.com or Whatsapp: +008615195010186. KYLT quote for your CNC Turning project online within 24hrs. 2D or 3D drawings are acceptable.

Introduction

Are you in need of precision machining services? Are you looking for high-quality CNC turned parts to meet your specific requirements? If so, you’ve come to the right place! In this comprehensive guide, we will introduce KYLT – CNC turning service and CNC turned parts manufacturing services, exploring the process, benefits, applications, and much more.

Photo shows Aluminum & Copper bars being turned and threaded by NC lathe, then assembled together. (Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

What is CNC Turning Service?

CNC turning service involves the use of Computer Numerical Control (CNC) machines or NC lathes to shape raw materials into desired components. This subtractive manufacturing process utilizes precision cutting tools to remove excess material from a workpiece, resulting in a finished product that meets precise specifications. CNC turning is particularly adept at producing cylindrical components with excellent dimensional accuracy and surface finish.

The photo shows a stainless steel part machined by CNC turning & milling, which has high precision, used in medical applications. (Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

CNC Turned Parts: The Building Blocks of Precision

1. The Significance of CNC Turned Parts

CNC turned parts play a crucial role in various industries, serving as essential components in complex machinery and equipment. These precision-engineered parts provide the foundation for seamless functionality and reliable performance in applications ranging from automotive and aerospace to electronics and medical devices.

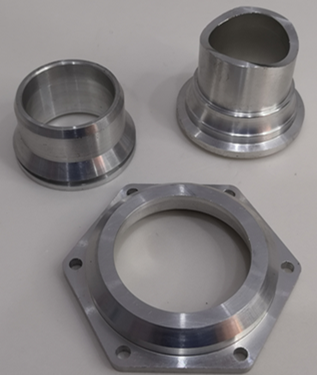

The photo shows Aluminum parts be machined by CNC turning & milling, which has high precision, used in Automobile modification.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

2. Versatility and Applications of CNC Turned Parts

The versatility of CNC-turned parts allows them to be used in an extensive range of applications. From intricate gears and shafts to threaded fasteners and connectors, CNC-turned parts are utilized wherever precision and reliability are paramount. Their exceptional dimensional accuracy, tight tolerances, and smooth surface finish make them ideal for demanding industries that require consistent and high-performance components.

The photo shows 4041HD steel CNC lathe turned pins with hard chrome plating.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

3. Materials for CNC Turned Parts

One of the notable advantages of CNC turning service is its ability to work with various materials. Whether your project requires the use of metals, plastics, or even exotic alloys, CNC-turned parts can be manufactured from a wide selection of materials to suit your specific needs. Common materials used for CNC turned parts include aluminum, stainless steel, brass, copper, titanium, and engineering plastics such as nylon and PEEK.

KYLT CNC Turning Service Materials:

- Steel: carbon steel -GB 45#, 30#, 20#, 40cr, H13, Q345, etc. F114, S355J2 …

- Stainless steel: 202, 304

- Copper / Brass

- Aluminum: 6061, 7075

- Graphite

- Laminate plate

- Laminated circle bar

- Plastics: PTFE, POM, PVC, NYLON

- Cast iron

- Wood

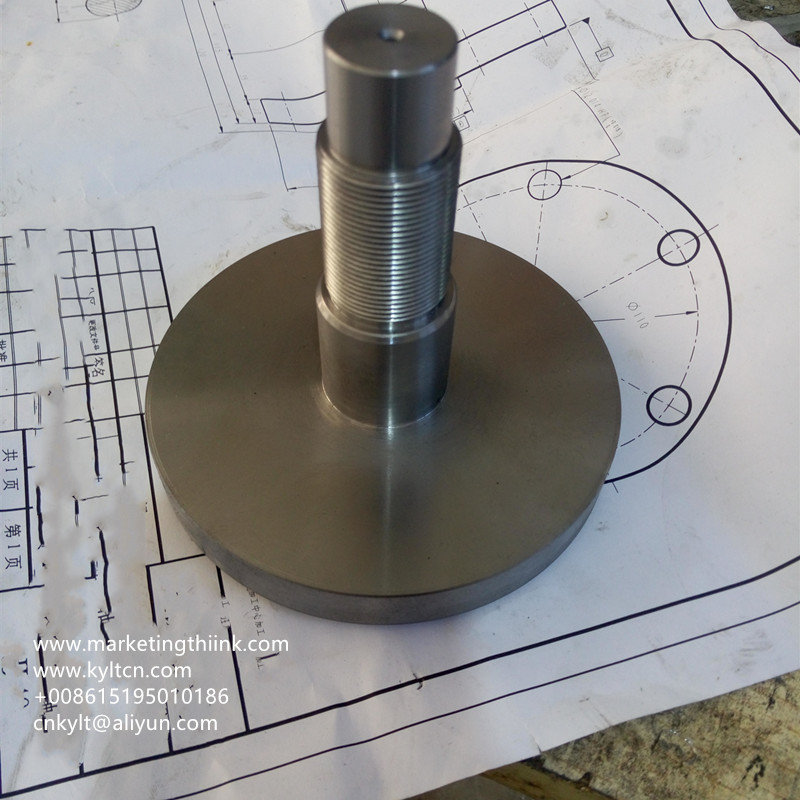

The photo shows an NC lathe turned carbon steel part, which has an external thread, used in machinery. (Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

4. Benefits of CNC Turned Parts

CNC-turned parts offer a plethora of benefits, making them the preferred choice for precision machining. Let’s explore some of the advantages:

i. Exceptional Precision and Accuracy

CNC turning service enables the production of parts with exceptional precision and accuracy. The advanced capabilities of CNC machines, coupled with computer-aided design (CAD) software, ensure that every dimension and detail of the component is manufactured to exact specifications. This level of precision is vital in industries where even the smallest deviation can lead to significant operational issues.

ii. Faster Production Times

With CNC turning service, the production of CNC turned parts can be completed at a faster rate compared to traditional machining methods. The automated nature of CNC machines allows for continuous operation and reduces the need for manual intervention. As a result, manufacturers can meet tight deadlines and fulfill orders promptly, enhancing overall efficiency and productivity.

iii. Cost-Effectiveness

While CNC machines may require a higher upfront investment, the long-term cost benefits outweigh the initial expenses. CNC turning service optimizes material usage, minimizes waste, and reduces the need for rework or scrap. Additionally, the precise machining capabilities of CNC turning result in fewer errors and defects, minimizing the costs associated with quality control and rejections.

iv. Design Flexibility and Complexity

CNC turning service provides design flexibility and the ability to create complex geometries that may be challenging or impossible with traditional machining methods. This allows engineers and designers to push the boundaries of innovation, creating intricate and sophisticated products.

The photo shows a CNC lathe turned with stainless steel parts, which are used in medical equipment with high precision. (Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

Advanced Techniques and Technologies in CNC Turning

CNC turning has evolved over the years, incorporating advanced techniques and technologies to further enhance its capabilities. Some notable advancements include:

i. Live Tooling

Live tooling is a feature available in some CNC lathes that allows for additional machining operations to be performed without the need to transfer the workpiece to another machine. These operations may include milling, drilling, and tapping, enabling the production of complex components with multiple features in a single setup. Live tooling expands the capabilities of CNC turning, reducing cycle times and increasing efficiency.

ii. Multi-Axis Machining

Traditional CNC turning machines operate in two axes: X and Z. However, with the advancement of technology, multi-axis machining has become increasingly prevalent. This enables the addition of rotational movement to the tool or workpiece, introducing additional axes such as Y, B, and C. Multi-axis machining allows for the creation of intricate geometries and contours, enhancing the versatility and complexity of CNC turned parts.

iii. Automation and Robotics

Automation plays a significant role in modern CNC turning operations. Robots and automated systems can be integrated into the workflow to perform tasks such as material handling, tool changes, and quality inspection. This reduces human intervention, increases productivity, and ensures consistent and repeatable results. Automated CNC turning systems are particularly beneficial for high-volume production runs and industries with stringent quality control requirements.

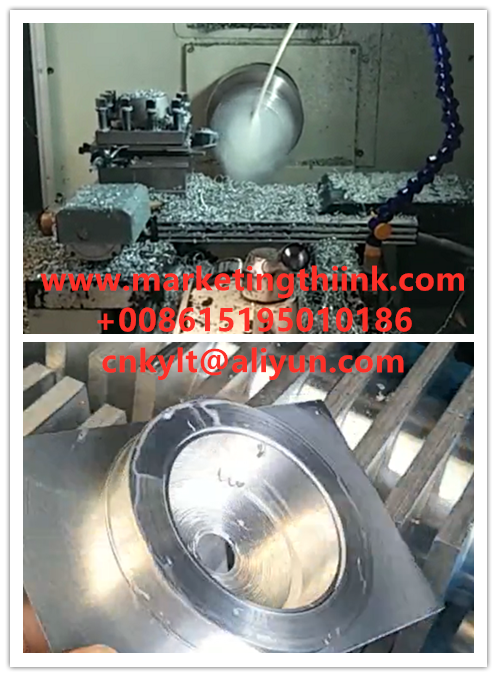

The photo shows an NC lathe turning process of an aluminum block. (Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

KYLT CNC Turning Service Range:

-Customized Aluminum, Steel, Stainless Steel, Plastic CNC Lathe Turned Parts Machining Services

-Magnesium, Aluminum Die Casting Part CNC Turned machining, Drilling & Tapping Services

-Other CNC turn parts or need to be machined by CNC lathe Turning

Get A Quote for your CNC Turned Parts Within 24hrs, Just send your drawings to: cnkylt@aliyun.com or Whatsapp: +008615195010186

Conclusion

CNC turning service and CNC turned parts are integral to precision machining and the manufacturing of high-quality components. The versatility, precision, and efficiency of CNC turning make it a preferred choice for industries that demand reliable and custom-engineered parts. Whether you require simple cylindrical components or intricate geometries, CNC turning can bring your designs to life with exceptional accuracy and surface finish.

KYLT is experienced in CNC turning, and NC lathe machining, Providing high-precision Aluminum, Carbon steel, Stainless steel, Magnesium, Copper, Plastic etc material turned parts manufacturing service. Get A FREE Quote for your CNC Turned Parts Within 24hrs, Just send your drawings to: cnkylt@aliyun.com

Frequently Asked Questions (FAQs)

1. What is the typical turnaround time for CNC turned parts?

The turnaround time for CNC turned parts depends on various factors, including the complexity of the component, the quantity required, and the workload of the machining facility. In general, CNC turning service offers relatively fast production times compared to traditional machining methods. Simple components with standard features may be produced within a few days, while more complex parts or larger quantities may require longer lead times. It is best to consult with your CNC turning service provider to get an accurate estimate based on your specific requirements.

2. Can CNC turning service accommodate custom designs?

Yes, CNC turning service is highly adaptable to custom designs. Whether you require unique geometries, specific tolerances, or special features, CNC turning can bring your custom designs to life. The ability to program CNC machines with precise specifications enables the production of highly customized CNC turned parts. It is essential to provide detailed design drawings or models to your CNC turning service provider to ensure accurate replication of your custom components.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

3. What are the typical tolerances achievable with CNC turning?

CNC turning is known for its ability to achieve tight tolerances and excellent dimensional accuracy. The achievable tolerances depend on factors such as the material, complexity of the component, and the capabilities of the CNC machine. In general, CNC turning can achieve tolerances within a few thousandths of an inch (0.001-0.005 inches) or even finer. However, it is important to discuss the desired tolerances with your CNC turning service provider to ensure that they can meet your specific requirements.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

4. Are CNC turned parts suitable for high-volume production?

Yes, CNC turned parts are well-suited for high-volume production due to the automation and efficiency of CNC turning service. CNC machines can operate continuously with minimal downtime, allowing for the production of large quantities of CNC turned parts in a relatively short period. Furthermore, CNC turning offers consistent and reproducible results, ensuring that each part meets the same high standards. For high-volume production, it is crucial to collaborate closely with your CNC turning service provider to optimize the manufacturing process and maximize efficiency.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

5. What are the advantages of outsourcing CNC turning service?

Outsourcing CNC turning service offers several advantages for businesses. Some of the key benefits include:

- Access to Expertise: By partnering with a reputable CNC turning service provider, you gain access to a team of skilled professionals with extensive knowledge and experience in machining. This expertise can contribute to the optimization of your designs, selection of materials, and overall manufacturing process.

- Cost Savings: Outsourcing CNC turning service can result in cost savings for your business. By leveraging the efficiency and productivity of specialized CNC turning facilities, you can reduce overhead costs associated with machinery, tooling, and maintenance. Additionally, the ability to scale production according to demand allows for better cost management.

- Focus on Core Competencies: Outsourcing CNC turning service enables you to focus on your core competencies and strategic initiatives. By entrusting the machining process to experts, you can allocate more time and resources to activities that drive innovation, product development, and market growth.

- Scalability and Flexibility: CNC turning service providers are equipped to handle projects of various sizes and complexities. Whether you require small batch production or high-volume runs, outsourcing allows for scalability and flexibility to meet your changing needs without incurring additional capital investments.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

6. How can I ensure the quality of CNC turned parts?

Ensuring the quality of CNC turned parts is essential to maintain the performance and reliability of your products. Here are some steps you can take to ensure quality:

- Partner with a Reputable Service Provider: Choose a CNC turning service provider with a proven track record of delivering high-quality components. Look for certifications, industry affiliations, and customer testimonials to gauge their expertise and reliability.

- Detailed Specifications: Clearly communicate your specifications and requirements to the CNC turning service provider. Provide accurate design drawings, tolerances, material specifications, and any special instructions. This will help ensure that the CNC turned parts are manufactured precisely to your specifications.

- Quality Control Measures: Work with your CNC turning service provider to establish robust quality control measures throughout the manufacturing process. This may include in-process inspections, dimensional measurements, surface finish evaluations, and final inspections. Regular audits and checks will help identify any deviations and ensure adherence to quality standards.

- Material Traceability: Request material traceability documentation for the raw materials used in the production of CNC turned parts. This ensures that the materials meet the required standards and can be traced back to their source in case of any issues or concerns.

- Continuous Improvement: Foster a collaborative relationship with your CNC turning service provider, encouraging open communication and feedback. Regularly evaluate the quality of the CNC turned parts and provide constructive feedback to drive continuous improvement and refinement of the manufacturing process.

(Precision CNC lathe turning service and CNC turned parts price, please email us: cnkylt@aliyun.com )

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology: