Injection Molding Service, Plastic injection molding is a manufacturing process that injects molten plastic to mold cavities to get final production-grade thermoplastic parts.

Injection molding has revolutionized the manufacturing industry, enabling the production of complex and intricate parts with remarkable precision and efficiency. This technique involves injecting molten material into a mold cavity, allowing it to cool and solidify, resulting in the formation of the desired product.

The versatility of injection molding has made it an integral part of various industries, including automotive, medical, consumer goods, and electronics. From small-scale components to large structural parts, injection molding offers unmatched capabilities in terms of design freedom, cost-effectiveness, and speed.

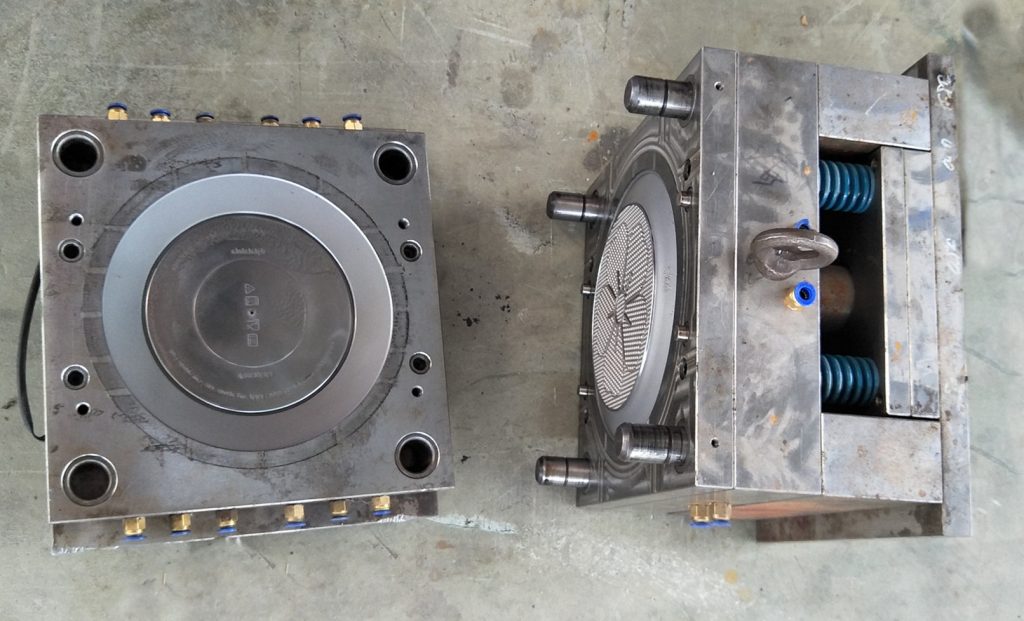

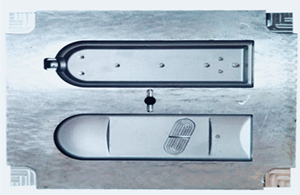

The photo shows a half plastic injection mold of PP plate, the PP material is food grade. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

KYLT Injection Molding Service for Custom Parts:

Plastic parts fast prototyping by CNC machining:

This is for some new testing project, custom just needs one or several pieces for testing and checking the function. We will make the plastic part by CNC machining, it is fast and high precision, no need to make plastic injection molds.

Bakelite Phenolic Resin Flat Plate Sheet Orange Electrical Glue Board Electric Plank machined by CNC prototype machining. To get a FREE quotation of your plastic molding products price or CNC rapid prototypes p, please Email us: cnkylt@aliyun.com

Fast Molded prototypes and low-volume production parts:

For some projects, we need to make a fast mold to mold plastic parts, and after this process, then make the long-life injection mold.

For common plastic, we can make mold directly.

Send us your 3D drawings to email: cnkylt@aliyun.com, you can get the quotation within 24hrs.

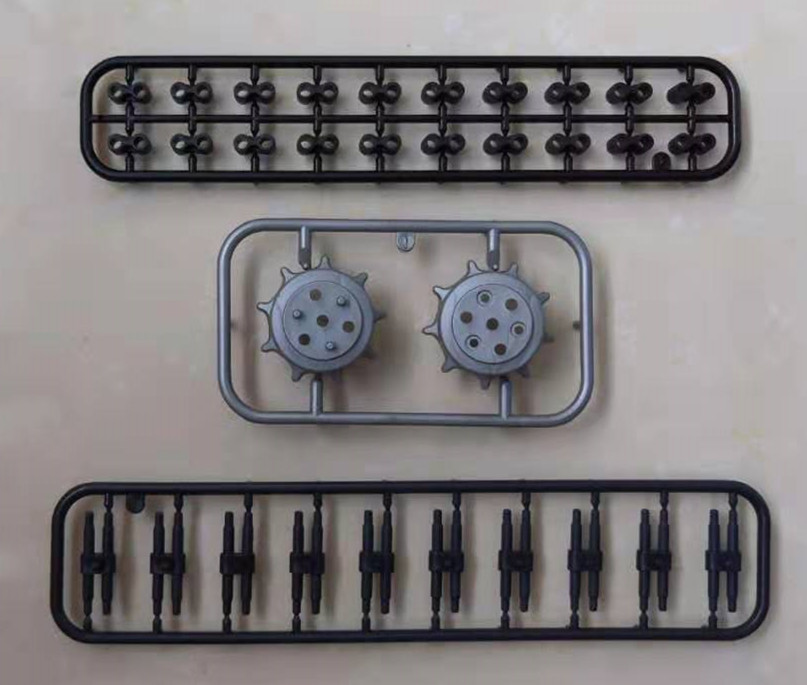

Photo shows PA66 Chair Ferrules Anti Scratch Floor Protector Table Feet Leg Cap End by plastic molding. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Photo shows PA66 Chair Ferrules Anti Scratch Floor Protector Table Feet Leg Cap End

Benefits of Injection Molding Service

Injection molding service offers numerous benefits that have contributed to its widespread adoption across industries. Let’s explore some of these advantages in detail:

- Cost-Effectiveness: Injection molding allows for mass production of parts, which significantly reduces the per-unit cost. With the ability to produce high volumes efficiently, businesses can enjoy economies of scale and minimize production costs.

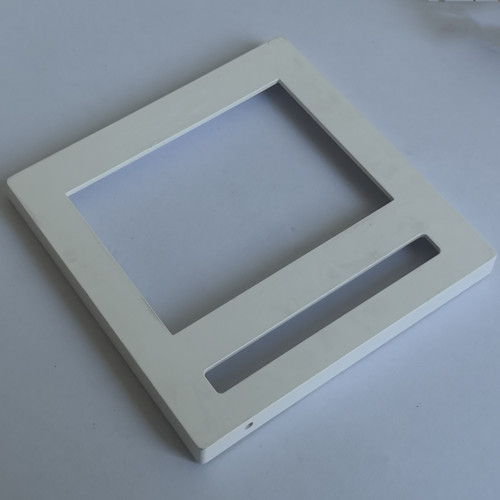

The photo shows a switch socket panel cover front structure, made of PC+ABS flame retardant material. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Design Flexibility: The design freedom provided by injection molding is unparalleled. Complex geometries, intricate details, and undercuts can be easily achieved with this process, giving manufacturers the freedom to create innovative and aesthetically pleasing products.

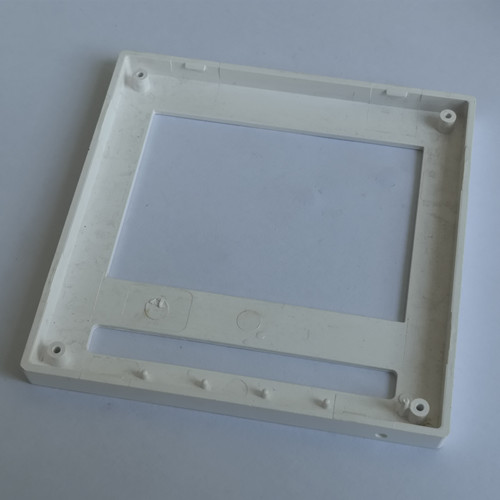

The photo shows a switch socket panel cover back side structure, made of PC+ABS flame retardant material. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- High Precision: Injection molding offers exceptional precision and repeatability, ensuring consistent quality in every part produced. The use of advanced automation and robotics further enhances accuracy, minimizing errors and variations in the manufacturing process.

The photo shows a (Round) switch socket panel cover front side structure, made of PC+ABS flame retardant material. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Fast Turnaround: The speed of injection molding is unmatched compared to traditional manufacturing methods. With rapid cycle times, manufacturers can produce a large number of parts quickly, meeting tight deadlines and satisfying market demands.

The photo shows a (Round) switch socket panel cover back side structure, made of PC+ABS flame retardant material. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Material Versatility: Injection molding accommodates a wide range of materials, including plastics, metals, elastomers, and composites. This versatility allows manufacturers to select the most suitable material for their specific application, considering factors such as strength, durability, and chemical resistance.

The photo shows a (Buttons) switch socket panel cover front side structure, made of PC+ABS flame retardant material. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Reduced Waste: Injection molding generates minimal waste compared to other manufacturing processes. The excess material can often be recycled and reused, promoting sustainability and reducing environmental impact.

The photo shows a switch socket panel cover, made of PC+ABS flame retardant material. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Key Components of the Injection Molding Process

To better understand the intricacies of injection molding, let’s examine the key components and stages involved in this manufacturing process:

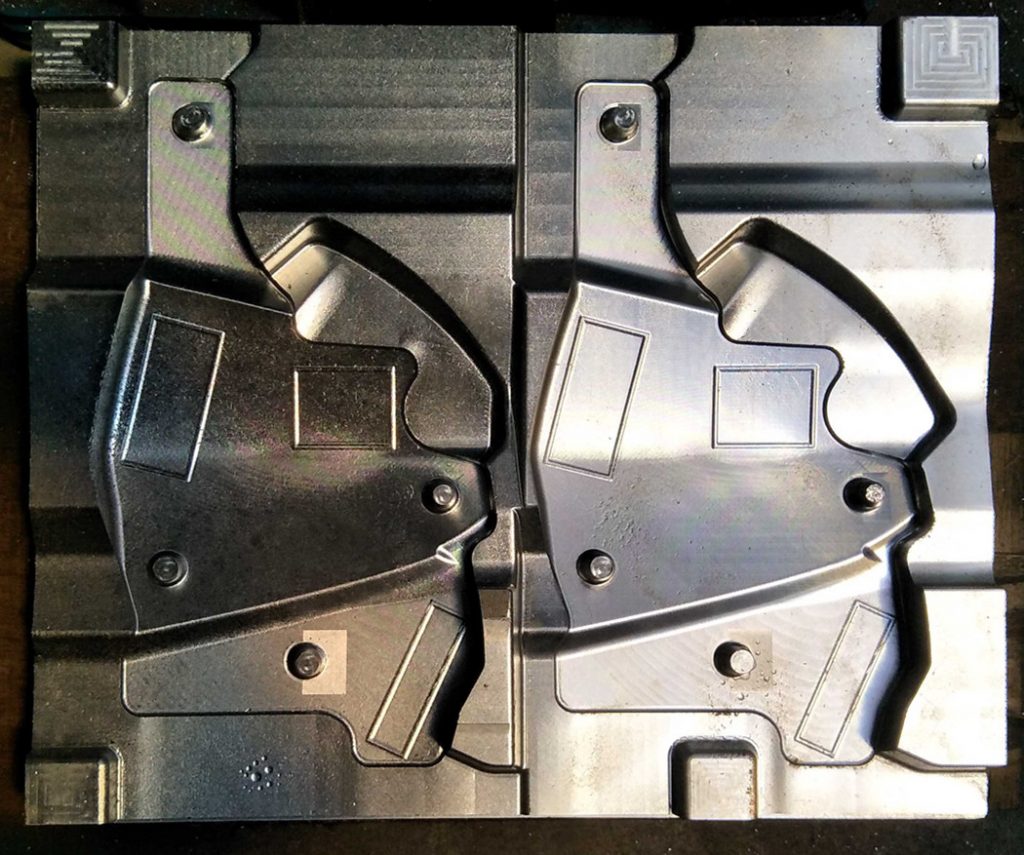

Mold Design and Tooling

Creating a mold that meets the desired specifications is a crucial step in injection molding. Skilled engineers and designers utilize computer-aided design (CAD) software to develop precise mold designs, taking into account factors such as part geometry, material flow, cooling channels, and ejection mechanisms.

Once the mold design is finalized, toolmakers use high-precision machining techniques to fabricate the mold. The mold consists of two halves, the cavity and the core, which are precision-machined to create the desired shape and dimensions of the final product.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Material Selection and Preparation

The choice of material plays a vital role in injection molding. The selection depends on factors such as the desired properties of the final product, environmental conditions, and cost considerations. Common materials used in injection molding include thermoplastics, thermosetting plastics, and elastomers.

Before injection, the material undergoes a preparation process, where it is melted and homogenized. This molten material is then injected into the mold cavity under high pressure.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Injection Molding Processes:

The injection molding process consists of several stages that ensure the successful creation of high-quality parts. Let’s explore each step in detail:

- Clamping: The first step in the injection molding process is clamping. The mold halves are securely closed and held together by a clamping unit. This unit applies sufficient force to keep the mold closed during injection and cooling.

- Injection: Once the mold is securely clamped, the molten material is injected into the mold cavity through a nozzle. The material is injected under high pressure to ensure complete filling of the mold and to minimize any defects or air pockets.

- Cooling: After the mold is filled with molten material, the cooling process begins. Cooling channels within the mold help dissipate heat and solidify the material. The cooling time is determined by factors such as material properties, part thickness, and complexity.

- Mold Opening and Ejection: Once the material has solidified, the mold is opened, and the part is ejected. Ejection pins or robotic arms assist in removing the part from the mold. The mold then closes again, preparing for the next injection cycle.

- Post-Processing: Depending on the specific requirements of the part, post-processing operations such as trimming, deburring, and surface finishing may be necessary. These operations ensure that the final part meets the desired specifications and quality standards.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Thermoplastic Injection Molding

KYLT can help you design and manufacture tools, dies, and molds for production runs. Full injection molding capabilities including insert molding, over-molding, and internal/external threads are available.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Mold Making & PLASTIC MOLDS TYPES:

As per your 3D drawings, We offer services from design and manufacturing for tools, dies, and molds for prototyping and production runs.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Over molding &Insert Molding

Over-molding and insert molding are two-part injection molding processes where one material is overlaid onto a second substrate part or metal insert to create a single multi-material component.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

For over-molding, one material, usually a thermoplastic elastomer (TPE/TPV), is molded onto a second material, which is often a rigid plastic.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Single cavity mold

This type of Mold contains only one cavity, per injection make one unit of plastic part.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

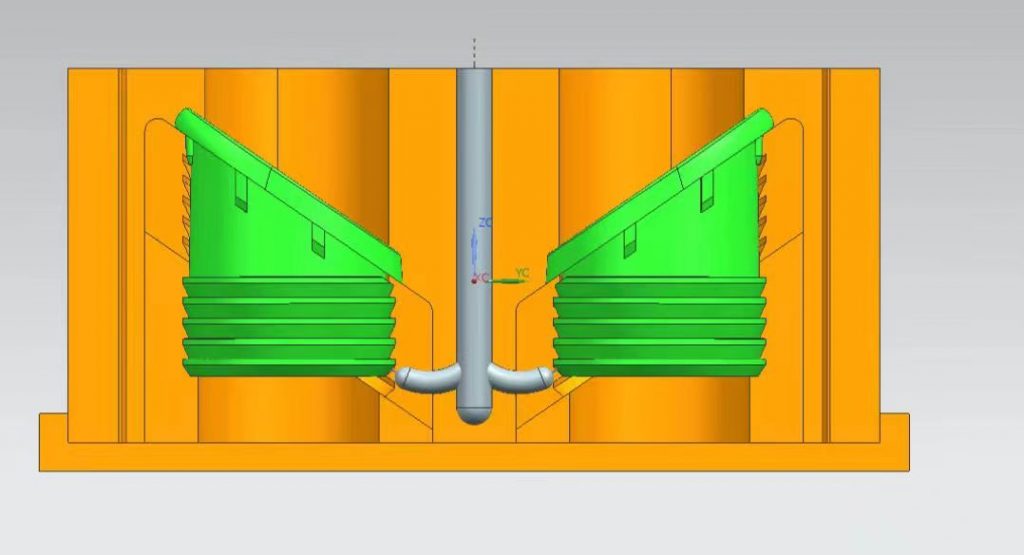

Molds with side-action cores/mold with sliders

It allows for undercuts to be molded. Cores slide out of the part from the side before it is ejected from the mold.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

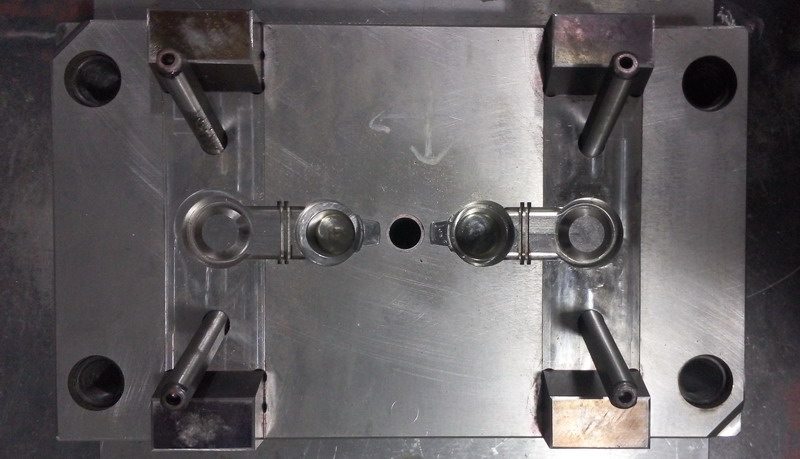

Multi-cavity molds

It allows more parts to be produced per injection, minimizing the unit costs. Multiple identical cavities are machined into the mold.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

Family Molds

Several parts which are made of the same plastic material, are designed into one mold. This allows for the minimization of tooling costs.

To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

GET A QUOTE FOR PLASTIC INJECTION MOLD PRICE

Applications of Injection Molding

Injection molding finds applications in a wide range of industries and product categories. Here are some notable areas where injection molding is commonly used:

- Automotive: Injection molding plays a crucial role in the automotive industry, enabling the production of interior components, exterior parts, and under-the-hood components. From dashboards and door panels to bumpers and engine covers, injection molding delivers durable and aesthetically pleasing automotive parts.

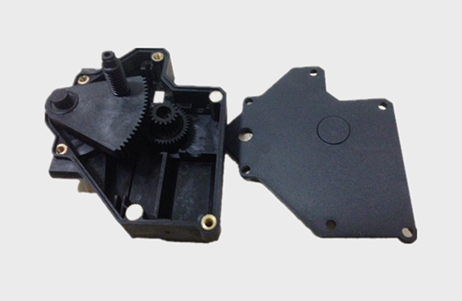

The photo shows some plastic auto headlight gear parts and gearbox assemblies, made of Nylon+Glass Fiber. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Medical: The medical industry relies heavily on injection molding for the production of precision medical devices, surgical instruments, and disposable products. The ability to meet strict quality standards, produce complex geometries and ensure biocompatibility makes injection molding ideal for medical applications.

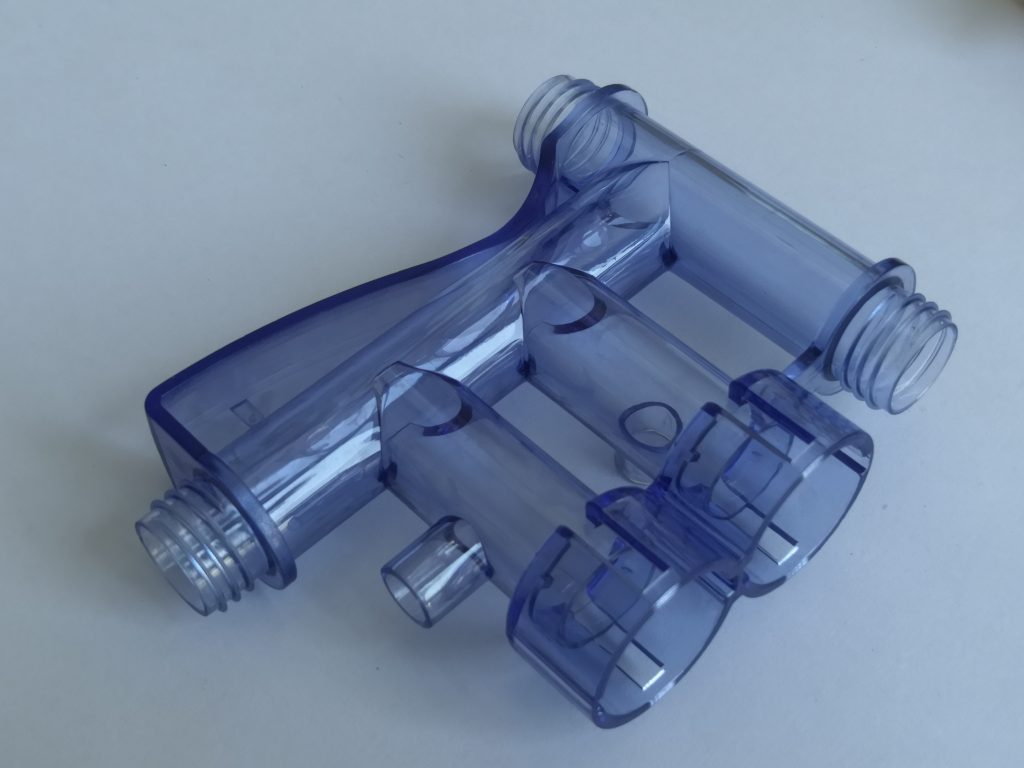

The photo shows a Disposable Suction Irrigation Device body by plastic injection molding, made of PP material. KYLT is experienced in many kinds of medical plastic parts mold making and manufacturing over 20 years. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Consumer Goods: Injection molding is widely employed in the production of consumer goods such as household appliances, electronic enclosures, toys, and packaging. Its ability to mass-produce intricate and functional designs at a low cost makes it a preferred choice for consumer goods manufacturers.

The photo shows chair spare parts by plastic injection molding. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Electronics: The electronics industry benefits from injection molding for the manufacturing of electronic housings, connectors, and intricate parts. The high precision and repeatability of injection molding ensure the proper functioning and protection of electronic components.

The photo shows Electronic Plastic Casing Enclosure Box for Adapter, and Mobilephone Laptop charger by plastic injection molding. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Industrial Equipment: Injection molding is utilized in the production of industrial equipment components such as gears, valves, and machine parts. The durability, strength, and dimensional accuracy offered by injection molding make it suitable for demanding industrial applications.

The photo shows the axle holder of machinery by plastic injection molding, made of Nylon + Glass fiber. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Aerospace: The aerospace industry relies on injection molding for the production of lightweight and durable components. From aircraft interior parts to structural elements, injection molding ensures the precision and reliability required in the aerospace sector.

- Food Packaging: Injection molding is widely used in the food packaging industry to create containers, lids, trays, and other packaging solutions. The process provides excellent product protection, hygiene, and customization options for food manufacturers.

- Cosmetics: Injection molding enables the production of cosmetic packaging, including bottles, jars, and caps. The process allows for intricate designs, branding elements, and customization, meeting the aesthetic and functional requirements of the cosmetics industry.

The photo shows a cosmetic bottle cap by plastic injection molding, made of PS + ABS, surface with color UV vacuum metallization coating. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Furniture: Injection molding is employed in the furniture industry for the production of chair components, table legs, and other structural parts. The process provides durability, strength, and design versatility to create aesthetically pleasing and functional furniture pieces.

The photo shows a connected part of a chair, which is used to connect different chair spare parts, made of PA66. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Sports Equipment: Injection molding plays a vital role in the production of sports equipment such as helmets, protective gear, handles, and grips. The process allows for the creation of lightweight yet durable components that meet the performance demands of athletes.

- Toys: Injection molding is the go-to manufacturing method for producing plastic toys. The process enables the creation of intricate designs, vibrant colors, and safe, child-friendly products that comply with stringent toy safety regulations.

- Electrical Components: Injection molding is widely used in the production of electrical components, including connectors, housings, and switches. The process ensures precise dimensions, electrical insulation, and resistance to various environmental factors.

The photo shows an electrical control panel box sheel by plastic molding. To get a FREE quotation of your plastic molding products price, please Email us: cnkylt@aliyun.com

- Pet Products: Injection molding is utilized in the production of pet products such as bowls, toys, and accessories. The process enables the creation of durable, non-toxic, and safe products for pets, catering to their specific needs and preferences.

- Promotional Items: Injection molding allows for the mass production of promotional items such as keychains, pens, and branded giveaways. The process ensures consistent quality, cost-effectiveness, and the ability to incorporate branding elements.

- Industrial Packaging: Injection molding is employed in the production of industrial packaging solutions, including pallets, crates, and containers. The process provides strength, durability, and stackability to safely transport and store industrial goods.

To get a FREE quotation of your plastic injection molds and plastic molding products price, please Email us: cnkylt@aliyun.com

Injection Molding Materials:

1. rigid plastic types:

- ABS: Common thermoplastic with high impact resistance, low cost & low density. Vulnerable to solvents.

- Acetal POM [Delrin]: Engineering thermoplastic with high strength, stiffness & moisture resistance, and self-lubricating properties. Relatively prone to warping.

- Acrylic (PMMA): UV-resistant plastic with good abrasion resistance, stiffness and hardness.

- High-Density Polyethylene (HDPE): Excellent strength-to-weight ratio, impact and weather resistant.

- Nylon 6 & Nylon 66: Engineering thermoplastic with excellent mechanical properties and high chemical & abrasion resistance. Susceptible to moisture. Nylon 66 is stronger than Nylon 6.

- PEEK: High-performance engineering thermoplastic with excellent strength and thermal & chemical resistance. Used to replace metal parts.

- Polycarbonate(PC): The plastic with the highest impact strength. High thermal resistance, weather resistance & toughness. Can be colored or transparent.

- Polypropylene(PP): The most common Injection molding plastic. Excellent chemical resistance. Food-safe grades are available. Not suitable for mechanical applications.

- Polyvinyl chloride(PVC): Light-weight plastic with good mechanical strength and abrasion resistance. Generally used in building and construction applications.

- PBT

- PC-PBT (Xenoy)

- PPE-PS

- PPS

- PSU

- PEI [Ultem]

The photo shows a custom plastic moulding part. To get a FREE quotation of your plastic injection molds and plastic molding products price, please Email us: cnkylt@aliyun.com

2. flexible plastic types:

- Low-Density Polyethylene (LDPE)

- PC-ABS : Blend of two thermoplastics resulting in high impact strength, excellent thermal stability, and high stiffness. Vulnerable to solvents.

- Polyethylene(PE) : Lightweight thermoplastic with good impact strength & weather resistance. Suitable for outdoor applications.

- Polystyrene(PS) :The Injection molding plastic with the lowest cost. Food-safe grades available. Not suitable for mechanical applications.

- PET

To get a FREE quotation of your plastic injection molds and plastic molding products price, please Email us: cnkylt@aliyun.com

3. rubber-like plastic types:

- TPE

- TPV

To get a FREE quotation of your plastic injection molds and plastic molding products price, please Email us: cnkylt@aliyun.com

INJECTION MOLDING WITH ADDITIVES AND FIBERS

- Colorants: Used to color plastics.

- Carbon fibers: Increase the strength, toughness, and rigidity of the material at the expense of making the material more brittle.

- Glass fibers: Increase the strength, toughness, and rigidity of the material at the expense of making the material more brittle. It is more flexible than carbon fibers.

- Flame retardants: Prevent ignition and inhibits the spread of fire.

- Plasticizes: Increase flexibility and promotes plasticity, reducing the brittleness of the material.

To get a FREE quotation of your plastic injection molds and plastic molding products price, please Email us: cnkylt@aliyun.com

PLASTIC INJECTION MOLDING PARTS SURFACE FINISHES

Glossy, Semi-gloss, Matte, Textured finish, Machined finish, Painting, Printing, Silk screen printing, Pad printing, UV coating…

INJECTION MOLDING DESIGN &INJECTION MOLDING COST

Upload your designs to : cnkylt@aliyun.com to got a free quotation.

More information about KYLT Plastic Molding Services, Plastic injection molds making Services, Please contact: cnkylt@aliyun.com +008615195010186

FAQs about Injection Molding Service

What is the cost of the injection molding service?

Injection molding costs vary depending on factors such as part complexity, material selection, and production volume. It is best to consult with a manufacturer to get an accurate cost estimate based on your specific requirements.

How long does the injection molding process take?

The duration of the injection molding process depends on factors such as part size, complexity, and material. Generally, the process can range from a few seconds to several minutes. Larger and more complex parts may require longer cycle times.

Can injection molding accommodate different materials?

Yes, injection molding can accommodate a wide range of materials, including various types of plastics, metals, elastomers, and composites.

What are the advantages of using injection molding for mass production?

Injection molding offers several advantages for mass production, including cost-effectiveness, high efficiency, consistent quality, and the ability to produce complex geometries. The process allows for the rapid production of large quantities of identical parts, making it ideal for meeting high-volume demands.

How does injection molding compare to other manufacturing processes?

Injection molding has several advantages over traditional manufacturing processes. It offers greater design flexibility, faster production times, reduced material waste, and cost savings. Additionally, injection molding allows for the production of intricate and complex parts with high precision.

What considerations should be taken into account when designing for injection molding?

When designing for injection molding, several factors should be considered. These include draft angles to facilitate ejection, the presence of undercuts and threads, wall thickness consistency, gate and runner design, and material selection. Consulting with experienced designers and engineers can ensure a successful injection molding process.

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology: