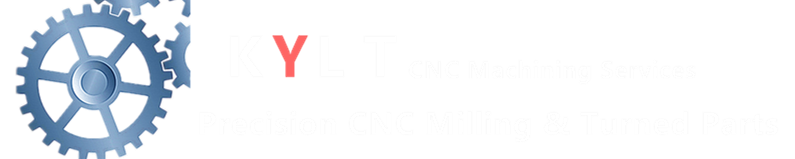

Scraping (spading) is an indispensable process in high-precision machines’ manufacturing . All guideways and spindles (sliding bearings) must be scraped to achieve the required accuracy. Scraping is the last process in scraping and grinding. It is to scrape the guideways surface with a scraper to produce regular patterns (usually crescent patterns).

Scraping/Spading has two functions: First, beauty. Secondly, the pattern has the function of oil storage, so that there is a layer of oil film on the surface of the guide rail.

Spade is a more difficult skill than wood carving. It is the starting point for the basic accuracy of precision tools. Scraping method eliminates our dependence on other tools, and also eliminates the deviation caused by gripping force and thermal energy.

The track of spade is less abrasive, which is attributed to the excellent lubrication effect. The spade technician needs to know many kinds of techniques, but only experience can make him grasp the feeling of achieving that precise leveling.

When you see technicians making shovels by hand, maybe you will wonder: “Can they really improve these machined surfaces by spade? Will people be more powerful than machines? “

If you mean purely its appearance, then our answer is “No”. We won’t do better, but why do SCRAPE? One of which is human factor: the purpose of the tool machine is to make other tool machines. But it can never replicate a product more accurate than the original. Therefore, in order to make a machine more accurate than the original machine, we must have a new starting point. That is to say, we must start with human efforts. In this case, artificial efforts refer to scraping by hand.

Scraping is not a “bare-handed” or “free-will” job. It is actually a method of reproduction. It almost perfectly reproduces the matrix, which is a standard plane and is also made by hand.

Although it is hard and arduous to scrape, it is a skill (art level technology). It may be more difficult to train a shovel master than to train a woodcarver. There are few books on this topic on the market, especially on “why scraping have less information”. Maybe that’s why scraping is regarded as an art.

Where to start scraping work?

If a manufacturer decides to grind with a grinder instead of spade, the accuracy of the guide of his “mother” grinder precision must higher than that of the newly built grinder.

So where did the accuracy of the first machine come from?

It must come from a more precise machine work-such as CNC machining, or depend on another way to produce a truly flat surface, or perhaps from a well-done flat surface.

We can use three ways of drawing circles to illustrate the process of surface formation (although circles are lines rather than surfaces, they can be cited to illustrate concepts). A craftsman can draw a perfect circle with an ordinary compass. If he uses a pencil to draw along a hole in a plastic template, he will copy all the inaccuracies of the hole. If he draws a circle with his bare hands, the accuracy of the circle depends on his limited skills.

In theory

A perfectly flat surface can be produced by alternating friction of three surfaces. For the sake of simplicity, let’s illustrate it with three rocks each with a fairly flat surface. If you alternately rub these three planes in random order, you will rub them more and more smoothly. If you only rub two rocks together, you will get a concave-convex mating pair. In practice, besides using spade to replace (polish Lapping), it also follows a clear pairing order. The spade master usually uses this rule to make the standard fixture (straight rule or flat plate) he wants to use.

In use

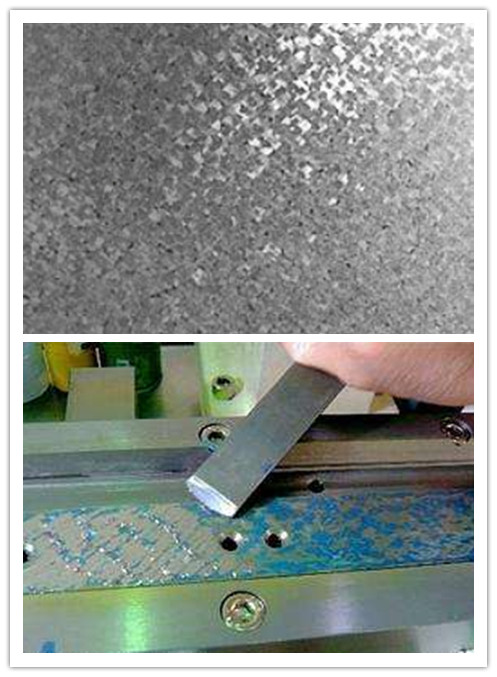

The spatula master will first coat the developer on the standard fixture, and then slide it on the surface of the workpiece to show where it needs to be shoveled. He repeats this action all the time, and the surface of the workpiece will be closer and closer to the standard fixture. Finally, he can perfectly reproduce the same work as the standard fixture.

Castings to spade are usually milled to a range of several thousandths larger than the final size, then sent to heat treatment to release the residual pressure, and then sent back to clean the surface before spade grinding. Although spade-shoveling takes a lot of time and labor costs, spade-shoveling can replace processes requiring high equipment costs. If spade-shoveling is not to be replaced by spade-shoveling operations, the workpiece must be finished with high precision and expensive machines.

In the final stage

Finishing involves not only high-cost equipment, but also a factor to be considered. When parts are processed, especially large castings, some action of gravity clamping is often necessary. When the precision of processing reaches a few thousandths, the force of this clamping often causes distortion of the workpiece. As for the accuracy of the workpiece after loosening the clamping force, the heat generated during processing can also cause distortion of the workpiece.

This is one of the many advantages of spade. Spade has neither clamping force nor almost zero heat. Cast iron is supported by three points to ensure that it does not deform by its own weight.

When the track of a tool machine needs to be shoveled again, it can be done by the maintenance staff of the factory, but we can also find someone to do the shoveling work locally.

Manual Scraping Or Electirc Scraping

In some cases, manual spade and electric spade can be used to obtain the final required geometric accuracy. If a group of worktable and saddle tracks have been leveled, and the accuracy has met the requirements. But found that the worktable on the parallelism of the spindle is not prescribed (it takes a lot of effort to correct), you can imagine using only a spade machine. Without losing the flatness, and can properly correct the alignment error, you can correct it. What level of technology is required to remove the correct amount of metal from the correct location?

Of course, this is not the original purpose of spade shoveling, nor should it be used as a method to correct large alignment errors. However, a skilled spade shoveler can complete this kind of correction in a surprisingly short time. Although this method requires skilled technology, it is more economical and economical than processing a large number of parts to a very accurate level, or making some reliable or adjustable designs to prevent alignment errors.

Improvement of lubrication

Practical experience has proved that spade track can reduce friction through better quality lubrication, but people are not sure why. The most common view is that spade lows (or, more specifically, pits cut for lubrication and more-done oil bags) provide many tiny oil storage pockets that will be scraped out by many tiny highs around them.

Another logical argument is that it allows us to maintain a continuous layer of oil film, allowing moving parts to float on the oil film, which is the goal of all lubrication. The main reason for this is that these irregular oil bags create a lot of room for oil retention, which makes it difficult for oil to run away. The ideal condition for lubrication is to maintain an oil film between two perfectly smooth surfaces, but then you have to deal with the problem of preventing oil from flowing out, or you need to replenish it as soon as possible. Whether or not spade is used on the track surface, oil ditches are usually made to help distribute the oil.

effect of contact area AFTER SCRAPING

Such a statement would raise questions about the effect of contact area. Spade spade reduces the contact area, but it will form a uniform distribution, and distribution is the focus. The smoother the two matching surfaces are, the more uniform the distribution of the contact surface is. But there is a principle in mechanics that “friction is independent of area”, which means that no matter the contact area is 10 or 100 square inches, the same force is needed to move the worktable. Friction is another matter. The smaller the area under the same load, the faster the friction is. )

The point I want to make is that what we are looking for is better lubrication, not more or less contact area. If the lubrication effect is perfect, the track surface will never wear out. If a worktable is difficult to move with wear, it may be related to lubrication, not to the contact area.

How is scraping/spading made?

The purpose of this section is not to teach the art of scraping, but to give you a concept of the process of shoveling. Although the actual operation is difficult, the concept behind the operation is quite easy.

Before finding out the highs that must be scraped out, first apply the developer on the standard fixture (flat or straight fixture for V-track shoveling) and then rub the standard fixture with the colorant on the track surface to shovel. The developer will transfer to the highs of the track surface, and then use a special spade tool to shovel the highs of the color. Eradicate. This action should be repeated until a uniform transfer occurs on the track surface.

Of course, a spade master should know all kinds of techniques. Let me start with two of them.

First, we usually use a blunt file to rub gently on the surface of the workpiece to remove the edges before we do the color rendering.

Second, wipe the surface with a brush or hand, never with rags. If the cloth is used to wipe, the fine linen left behind by the cloth will cause misleading marking in the next highlight rendering.

The spade shoveler will check his work by comparing the standard fixture with the track surface. The inspector only needs to tell the spade shoveler when he can stop his work, so he doesn’t have to worry about the spade process. (Flower shovelers can be responsible for the quality of their work.)

In the past, we all had a set of criteria to specify how many high points each square inch should have and how much percentage of the total area should have, but we found it almost impossible to check the contact area, and now it is up to the shoveling master to decide the number of points per square inch. In short, spade shovelers generally strive to meet the standard of 20 to 30 points per square inch.

THE USE OF MANUAL & ELECTRICAL SPADING

Now in the process of spade shoveling, some leveling operations use electric spade shovelers, they are also a kind of manual spade shoveling, but can eliminate some laborious work, so that spade shoveling operation is less tired. When you do the most sophisticated assembly work, the feeling of manual spade is still irreplaceable.

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology: